250T 300T Hydraulic Track Press for the Assembly Disassembly of Track Chains

Product Description

| Technical paramter: | ||

| 1 | Hydraulic press | 300T |

| 2 | RAM SPEED FORWARDS AND REVERSE | 190X2mm |

| 3 | Worktable Height Adjustment | 825mm |

| 4 | Motor power | 11KW |

| 5 | PUMP FLOW RATE | 40ML |

| 6 | PUMP PRESSURE: | 36MPa |

| 7 | Press link machine dimension | 1880X580X1350MM |

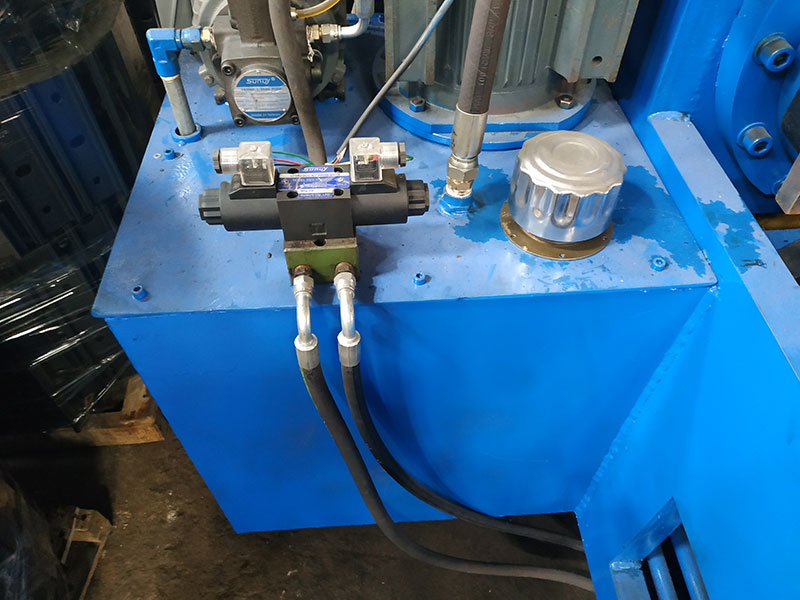

| 8 | HYDRAULIC OIL TANK CAPACITY | 150L |

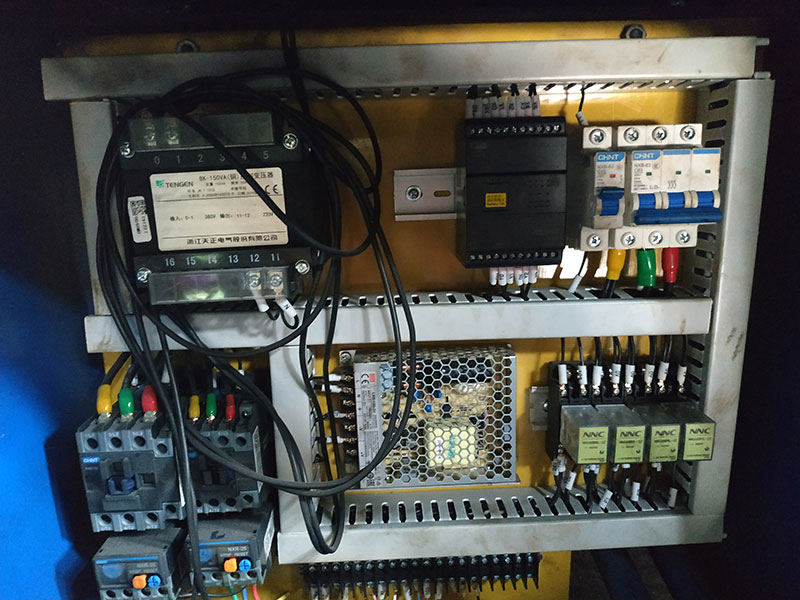

| 9 | Voltage | 380V 50Hz three-phase |

| 10 | Pitches | ≤317mm |

| 11 | Model | Fit for PC60-PC400,D20-D355,D9N |

| Type | Fit for Pitch (mm) | Mould Qty | Fit mchine | Efficiency |

| Example of Komatsu | ||||

|

Manual Press Link Machine (weight about 250kgs) |

175,190 |

1 |

PC100,PC200 | About 15-20 mins |

| 175,190,203 |

2 |

PC100,PC200, | ||

| PC300 | Per link section | |||

| 175,190,203,216 |

3 |

PC100,PC200, | ||

| PC300,PC400 | ||||

|

175,190,203,216,228 |

4 |

PC100,PC200, | ||

| PC300,PC400-6 | ||||

| Only for 280 |

1 |

PC600,D9,D10 | ||

|

Manual & Electronic Press Link Machine (weight about 300kgs) |

175,190 |

1 |

PC100,PC200, | About 7-10mins |

| 175,190,203 |

2 |

PC300 | ||

| 175,190,203,216 |

3 |

PC100,PC200, | ||

|

175,190,203,216,228 |

4 |

PC100,PC200,PC300,PC400-6 | Per link section | |

| Only 280 |

1 |

PC600,D9,D10 |

Track press machine Operation instruction:

1. Connect the power, the control panel power indicator light.

2. Install and adjust the tip tool corresponding to the picth of link.

3. Install W-type tools for Removing the chain.

4. Support the square tool between the W tool and the left cylinder before removing the link.

5.The tip tools of the removing link pin change to the front for easy operation, with the H-type tool to secure the chian pin, pull the right cylinder remove chian pin.

6.The W-type tools change to flat-panel tools for assembling chain.

7. Install the fixed tool on the left cylinder.

8. Pull the left side of the fixed tool to the left of the chain corresponding to the picth position, and then placed the chain pieces, chain pins,dust washers.

9. H shape track hole size tool can be smoothly into the hole, said the press size in place,the chain assembly.

Pay attention :

1.We must fill antifriction oil into the oil tank before start the operation

2.Please inspect the motor is under the corotation condition (please check the motor corotation mark) 3.Up and down board has been already tuned, please don’t adjust casually

4.When assembling the track link section, please adjust the mold according to the link pitch

5.When disassembling the tracking link, please fit the disassembly head in one side of the cylinder,and use the guard to ward off the track link in other side of the cylinder