bulldozer dozer grader blade end bits cutting edge for 220-9097 and equipment used carbon boron steel 220-9099 220-9094 220-9112

This is applicable for bulldozer

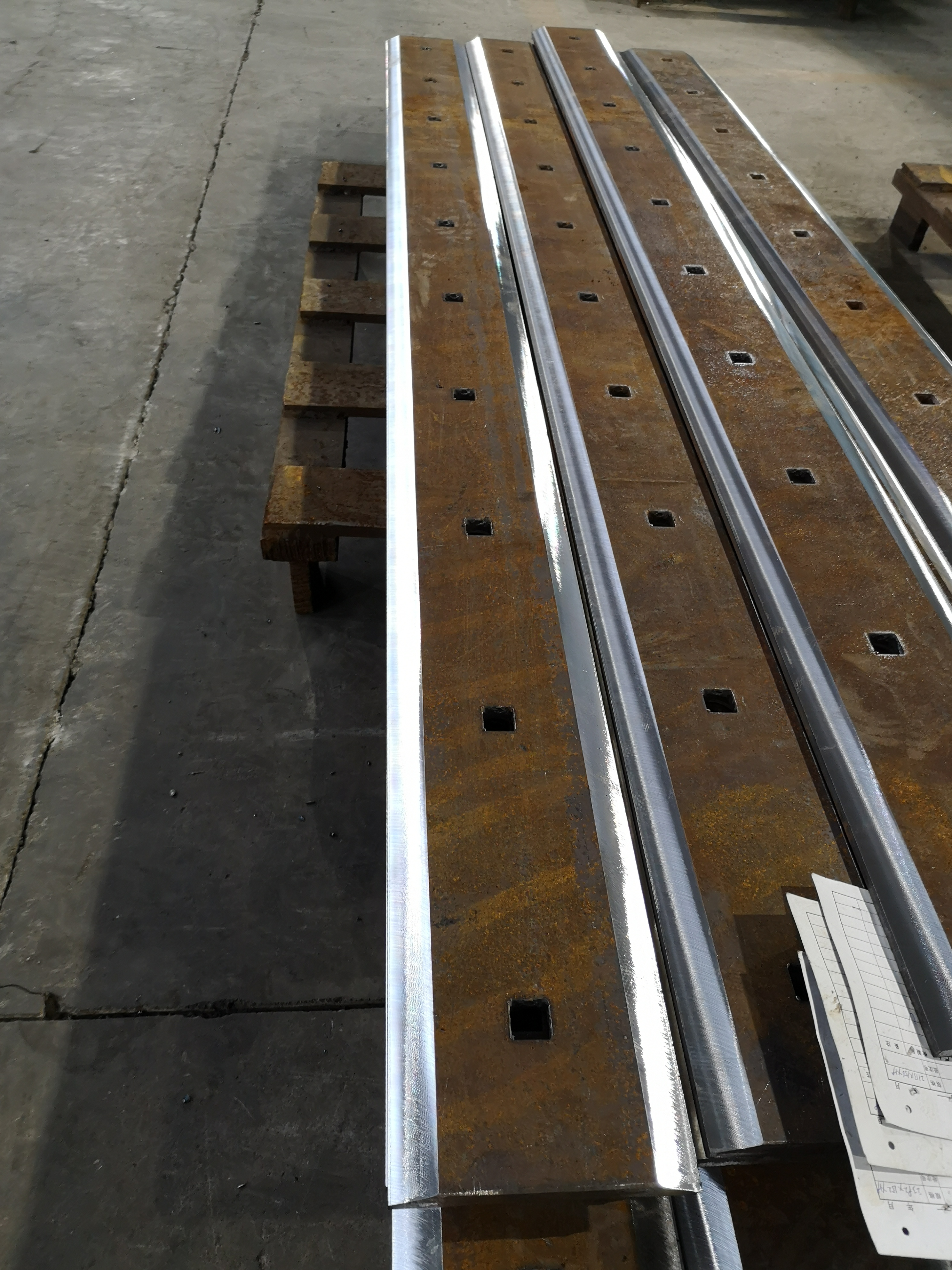

All our Parts are through hardened to 440-520HB and have yield strength of 1440N/mm2.Advantage of using Heat Treated Boron Material Ground Engaging Tools.

The above technical data shows that the Boron type of GET has superior mechanical properties with much higher resistance to wear and abrasion due to the nature of chemical composition. As a result,

the lifespan of Boron type of GET will be at least twice that of carbon steel. Thus, the cost savings on downtime, labor charges and plow bolts and nuts are tremendous.

Chemical Composition:

| Element | Boron Steel | Carbon Steel |

| C | 0.26-0.30 | 0.80-0.85 |

| Si | 0.15-0.30 | 0.15-0.35 |

| Mn | 1.10-1.40 | 0.55-0.80 |

| P | 0.03 max | 0.03 max |

| S | 0.03 max | 0.03 max |

| Cr | 0.30-0.50 | 0.03 max |

| B | 0.0005-0.003 |

Mechanic Proper with Heat Treatment:

| Element | Boron Steel | Carbon Steel |

| Hardness | 440-520HB | 280-320HB |

| Yielding Point | 1440N/mm2 | 600Re-N/mm2 |

| Breaking Point | 1674N/mm2 | 1030RM/N/mm2 |

| Elongation | 11% | 12% |

| Resilience at-20/C | 51J | 6J |

Advantage

Packaging & Shipping

FAQ

1. You are a trader or a manufacture?

We are an industry and trade integration business, our factory located on Quanzhou Nanan Distric, and our sales department is in City centre of Xiamen. The distance is 80Kms, 1.5 hours.

2. How can I be sure the part will fit my excavator?

Give us correct model number/machine serial number/ any numbers on the parts itself. Or measure the parts give us dimension or drawing.

3. How about the payment terms?

We usually accept T/T or L/C. other terms also could be negotiated.

4. What is your minimum order?

It depends on what you are buying. Normally, our minimum order is USD5000. one 20’ full container and LCL container (less than a container load) can be acceptable.

5. What is your delivery time?

FOB Xiamen or any Chinese port : 35-45 days . If there are any parts in stock , our delivery time is only 7-10 days.

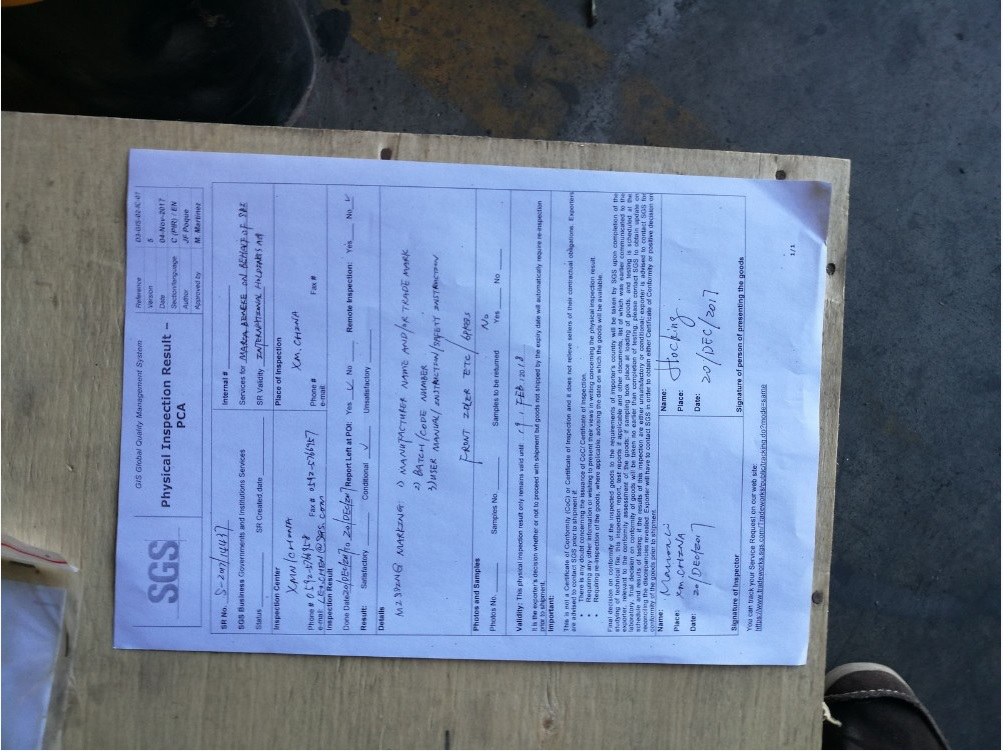

6. What about Quality Control?

We have a perfect QC system for the perfect products. A team who will detect the product quality and specification piece carefully, monitoring every production process until packing is complete, to ensure product safety into container.