D5,D6 single rock shank ripper for dozer 32008082

Product information.

(1)One-piece without welding

(2)Forging, High resilience to prevent breakages

(3)It is one of the most common, strong, durable, efficient, which commonly used to loose rock

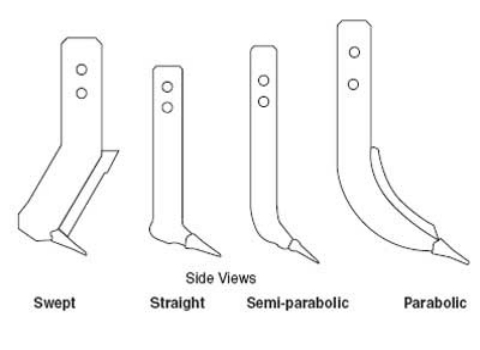

Shank Designs

Parabolic shanks (figure 4a) require the least amount of horsepower to pull. In some forest applications, parabolic shanks may lift too many stumps and rocks, disturb surface materials, or expose excess subsoil. Swept shanks tend to push materials into the soil and sever them. They may help keep the subsoiler from plugging up, especially in brush, stumps, and slash. Straight or "L" shaped shanks have characteristics that fall somewhere between those of the parabolic and swept shanks.

Figure 4a—Shank designs include: swept, straight or "L" shaped, semiparabolic,

and parabolic. Shank design affects subsoiler performance, shank strength,

surface and residue disturbance, effectiveness in fracturing soil, and the

horsepower required to pull the subsoiler.

Shanks should be designed to handle rocks, large roots, and highly compacted soils.

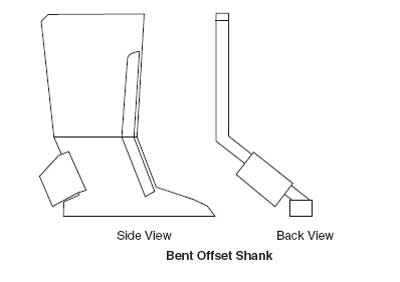

Shanks usually are from ¾ to 1½ inches thick. Thinner shanks are suited for agricultural use. Thicker shanks hold up better in rocky conditions, but require larger, more powerful equipment to pull them and disturb the surface more. Bent offset shanks, such as those found on Paratill subsoilers, have a sideways bend (figure 4b). Some testing has shown that bent offset shanks disturb surface residue less than straight shanks.

The typical spacing is 30 to 42 inches between shanks. Shanks should be able to reach 1 to 2 inches below the deepest compacted layer.

Figure 4b—Bent offset shank.

Shank spacing and height should be adjustable in the field. Towed subsoilers should have gauge wheels to control the shank's depth. Conventional ripper shanks, typically found on dozer equipment, work reasonably well when winged tips are added and may be suitable for many jobs and locations.

product list

| NO. | Name | PART NO. | MODAL | TOOTH POINT | PROTECTOR | U'WT(KG) |

| 1 | SHANK | 9J3199 | D5,D6 | 63 | ||

| 2 | SHANK | 32008082 | D5,D6 | 65 | ||

| 3 | ADAPTER | 8E8418 | D8K,D9H | 9W2451 | 6J8814 | 75 |

| 4 | SHANK | 8E5346 | D8N,D9N | 9W2451 | 8E1848 | 289 |

| 5 | SHANK | D9R | D9R | 4T5501 | 9W8365 | 560 |

| 6 | SHANK | D10R | D10 | |||

| 7 | SHANK | D10 | ||||

| 8 | SHANK | 118-2140 | D10 | 6Y8960 | 745 | |

| 9 | SHANK | 8E8411 | D10N | 4T5501 | 9W8365 | 635 |

| 10 | SHANK | 1049277 | D11 | 9W4551 | 9N4621 | 1043 |

| 11 | ADAPTER | 1U3630-HC | 4T5501 | |||

| 12 | ADAPTER | 1U3630 | 133 |

| Shantui | ||||

| No. | Description | Part No. | Model | Weight |

| 1 | Ripper Shank | 10Y-84-50000 | SD13 | 54 |

| 2 | Ripper Shank | 16Y-84-30000 | SD16 | 105 |

| 3 | Ripper Shank | 154-78-14348 | SD22 | 156 |

| 4 | Ripper Shank | 175-78-21615 | SD32 | 283 |

| 5 | Ripper Shank | 23Y-89-00100 | SD22 | 206 |

| 6 | Ripper Shank | 24Y-89-30000 | SD32 | 461 |

| 7 | Ripper Shank | 24Y-89-50000 | SD32 | 466 |

| 8 | Ripper Shank | 31Y-89-07000 | SD42 | 548 |

| 9 | Ripper Shank | 185-89-06000 | SD52 | 576 |

| 10 | Ripper Shank | 1142-89-09000 | SD90 | 1030 |

| 11 | Ripper Tooth | 175-78-31230 | SD16,SD22,SD32 | 15 |

1.The specifications and types of our buckets are applicable to over 90 kinds of excavators such as HITACHI, KATO, SUMITOMO, KOBELCO, DAEWOO, HYUNDAI,etc. According to different operating conditions, various kinds of buckets arereasonably designed from shapes, materials, thickness of plates, and stress features,etc. The bucket capacity is from 0.25 m3 to 2.4 m3. Advanced digital controlflame (plasma) cutting machines, large lapping machines, and CO2 protectivewelding machines guarantee the quality of our products.

1)Categories and Main Differences of Buckets 1.General Buckets: Standard bucket materials and quality homemade tooth holders.

2)Reinforced Buckets: Quality structural steel with high strength and quality homemade

tooth holders.

3)Rocky Buckets: Wear resistant steel with high strength, reinforced high stress

parts, thicker abrasive parts, reinforcing ribs at bottom, and rock-oriented SBIC

products from South Korea.

2.Applications of Buckets General Buckets Light duty operations like the excavation of clays and the loading of sand,earth, and gravel, etc. Reinforced Buckets Heavy duty operations like the excavation of hard soil, earth mixed with soft stones,and soft stones and the loading of breakstones and gravels. Rocky Buckets Heavy duty operations like the excavation of earth mixed with hard stones, solid rocks, and weathered granite and the loading of solid rocks and dynamited ores.

3.The Chemical Ingredients and Mechanical Performance Comparison of Three Materials:

KM