Forging Process of Bucket Teeth & Adapter

We all know that all the investment castings consist of lots of manufacturing procedures. CFS bucket teeth adopt investment casting technique, also called lost wax casting, including wax pattern injection, tree assembly, shell building, dewax, metal casting and other post treatments. The biggest advantage of investment casting is that it can obtain high size accuracy, good surface finish, and cast all alloy complex shapes.

Below are the casting processes of bucket teeth in our foundry in each step:

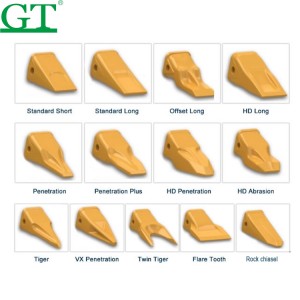

Step 1. Design bucket teeth in different apperance and dimensions according to the market demand.

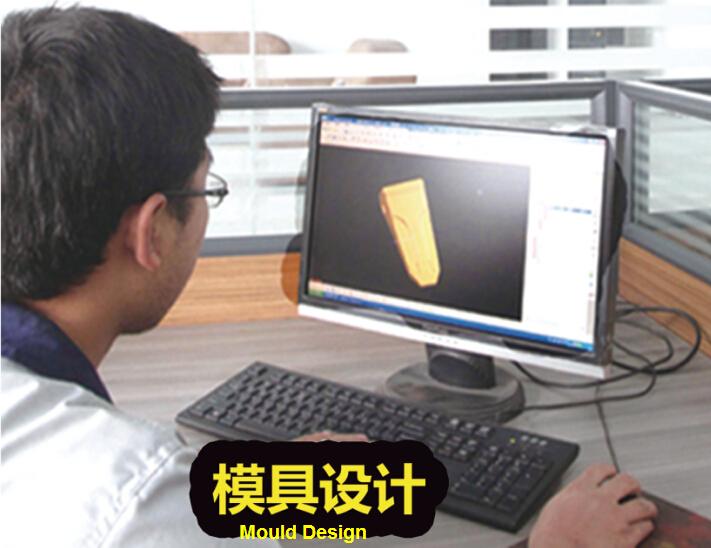

Step 2. Equipped with full set mould processing equipment and professional technical team, we can machine tooling for all kinds of investment casting, including bucket teeth.

Step 3. Wax pattern making is the first step for casting bucket teeth. Wax pattern is used to form the cavity of refractory shell. So to achieve quality bucket teeth with high size accuracy and surface finish, the wax model itself should have such high accuracy and surface finish. But how to get qualified wax pattern? Besides design good mould, we still need to choose excellent wax material and proper wax pattern process. Advantages of wax models from CFS are low melting point, good surface finish & dimensions, high strength and light weight.

Step 4. Tree assembly is the process that sticking wax patterns of bucket teeth to sprue gating system.

Step 5. Main procedures of shell building include:

a. Unoil of tree assembly–To improve the ability of coating wetting ability, we need to remove the surface oil of wax models.

b. Dipping tree assembly into ceramic coating and spraying sand on the surface.

c. Dry and harden ceramic sheel. Each time coating of ceramic sheel layer needs to be dried and hardened.

d. After completely hardening of ceramic shell, we need to remove wax mould from shell, this process is called dewax. According to different heating methods, there are lots of dewax ways, mostly used is same pressure steam method.

e. roasting ceramic shell

Step 6. Pouring metal liquid alloy to fill the cavity of shell.

Step 7. Cleaning of casting bucket teeth, includes remove shell, sprue section, attached refractory material and cleaning after heat treatment like scales.

Step 8. After heat treatment, the organizational structure of bucket teeth will be uniform, and the wear resistance will be greatly improved, so that the serving life will improve twice than before.

Step 9. By complete inspection of material and mechanical properties for bucket teeth, we can effectively prevent unqualified products to market.

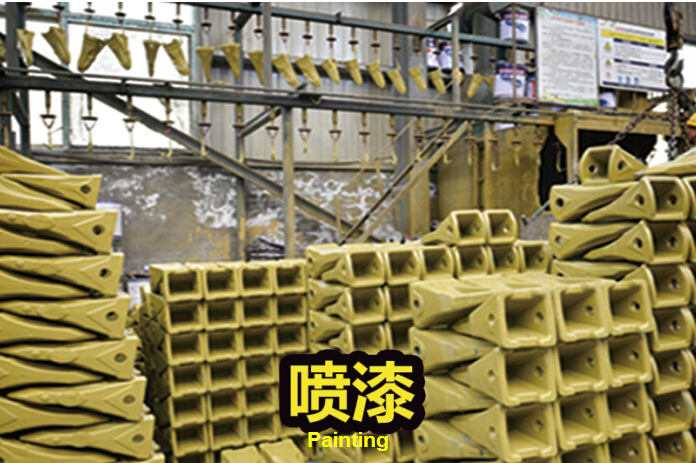

Step 10. Painting in colors like yellow, black, green, ect to fit different brands and machines.

Step 11. Pack bucket teeth in standard wooden case from any damage and deliver to our customer.