Forging Segment for Shantui Komatsu CAT

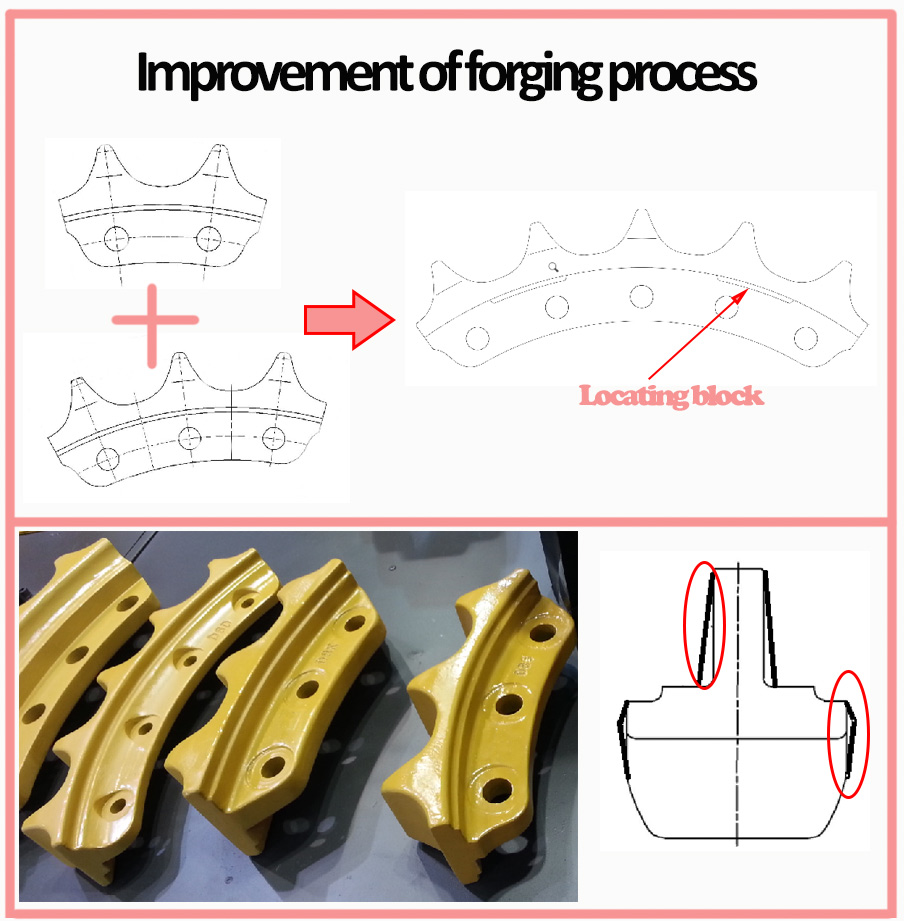

Improvement of forging process

Changing from two or three teeth to five teeth reduces the occurrence of tooth block loosening. Changing the positioning circle to a positioning block reduces machining errors and interference between the positioning circle and the installation surface caused by heat treatment deformation.

Due to the forging process, the side and flange surfaces of the segment in the upright forging process need to retain a certain draft angle, and the machined surface of the forged semi-finished product must be processed.

Model We Can Supply

| SEGMENT | ||||||||

| Model | OEM | Pitch | Tooth | Hols | Aperture(mm) | Weight | Brand | Other OEM(BERCO) |

| DH08 | 111H-18-00001 | 154 | 3 | 3 | 17.5 | 4.1 | shantui | |

| 111H-18-00002 | 4 | 4 | 17.5 | 5.5 | shantui | |||

| SD13 | 10Y-18-00043 | 190 | 5 | 5 | 19.3 | 10.75 | shantui | |

| DH36 | 1175-18-00009 | 228.6 | 6 | 6 | 26.5 | shantui | ||

| 1175-18-00035 | 5 | 5 | 26.5 | |||||

| SD16、D65、D60、D85ESS-2 | 16Y-18-00014H | 203.2 | 3 | 3 | 23.5 | 8.5 | shantui/komatsu | 14X-27-15112/1,141-27-32410,144-27-51150,615-4149,KM2111,KM162 |

| (16Y-18-00049) | ||||||||

| SD22、D85 | 154-27-12273A | 216 | 5 | 5 | 23.5 | 15 | shantui/komatsu | 155-27-00151,615-4150,KM224 |

| SD32 、D155 | 175-27-22325A | 228.6 | 3 | 3 | 26.5 | 12 | shantui/komatsu | 175-27-22325/4 17A-27-11630,KM193,17A-27-41630 |

| SD52、D375 | 185-18-00001 | 280 | 5 | 5 | 28.5 | 33 | shantui/komatsu | 195-27-33110/1,KM1285 |

| SD90、D475 | 1189-18-00001/ | 317.5 | 5 | 5 | 31.5 | 43 | shantui/komatsu | |

| 198-27-42260 | ||||||||

| D50、D41、D58、D53 | 131-27-61710 | 175 | 3 | 3 | 19.5 | 6 | komatsu | 131-27-61710、131-27-42220、KM788 |

| D5B | 5S0836 | 175 | 3 | 3 | 18 | 5 | CAT | 6Y5244、CR4408.7P2636 |

| D6D/C/G | 6T4179/6T4179/6P9102 | 202.8 | 5 | 4 | 17.8/20.8 | 11.57 | CAT | 6Y5012,5S0050,7P2706,CR3330,CR3329,8P5837,8E4365/CR5476,117-1616 |

| D6H/R | 6Y2931/1026677 | 202.8 | 5 | 5 | 17.8 | 11.5 | CAT | 7G7212,8E9041,7T1697,CR5515,173-0946 |

| D7G/E/F | 8E4675/8E4675/8E4675 | 216 | 5 | 4 | 20.8 | 14.7 | CAT | 5S0052,3P1039,8P8174,CR3148 |

| D8N/R.D7H/R | 7T9773/6Y2354, | 215.9 | 5 | 7 | 20.8 | 16.4 | CAT | 6Y3928,CR5050,9W0074 |

| 6Y2354/7T9773 | ||||||||

| D8N/R.D7H/R | 314-5462 | 215.9 | 5 | 5 | 20.8 | 16.4 | CAT | CR7160 |

| D8K.D8H | 6T6782/6T6782 | 228.6 | 3 | 3 | 24.5 | 12 | CAT | 2P9510,5S0054,CR3144 |

| D6N.D6M | 6I8077/6I8077 | 190 | 5 | 5 | 18.5 | 9 | CAT | 6I8077/8,CR5875 |

| D9N | 7T1247 | 240 | 5 | 6 | 24.6 | 23.98 | CAT | CR4686 |

| D10N | 6T9537 | 260.35 | 5 | 6 | 27.61 | 26.7 | CAT | CR5047 |

| 832 | 632-7793 | 228.6 | 3 | 5 | 26.5 | 11.63 | CAT | |

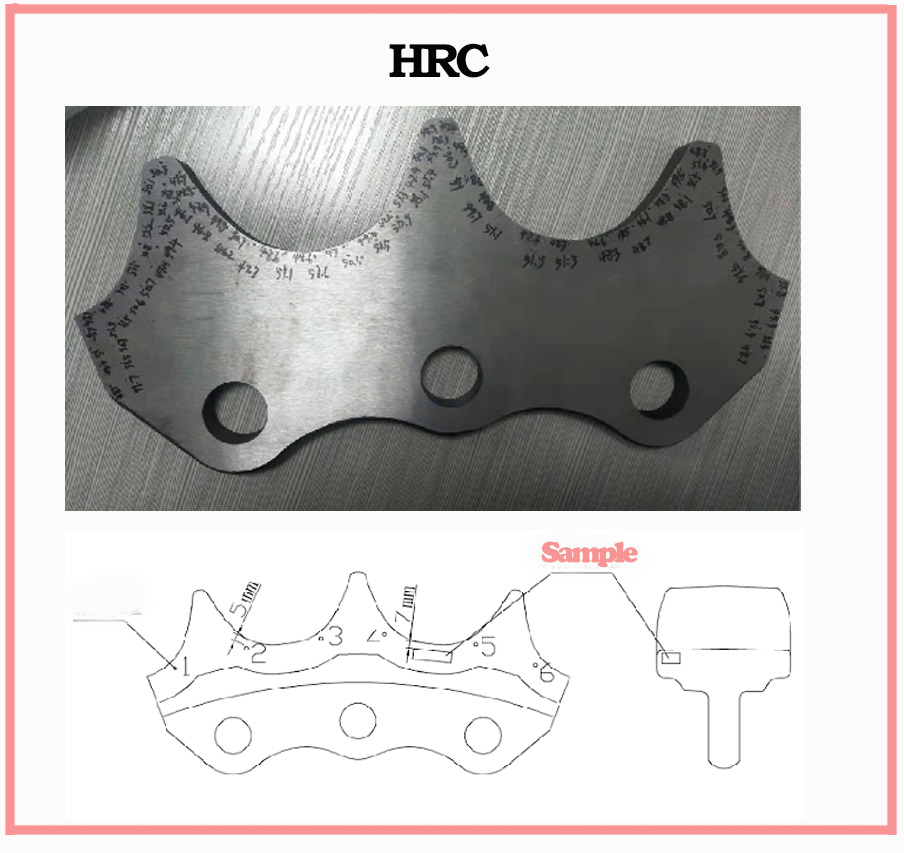

HRC

Due to the forging process, the side and flange surfaces of the segment in the upright forging process need to retain a certain draft angle, and the machined surface of the forged semi-finished product must be processed.

Packing