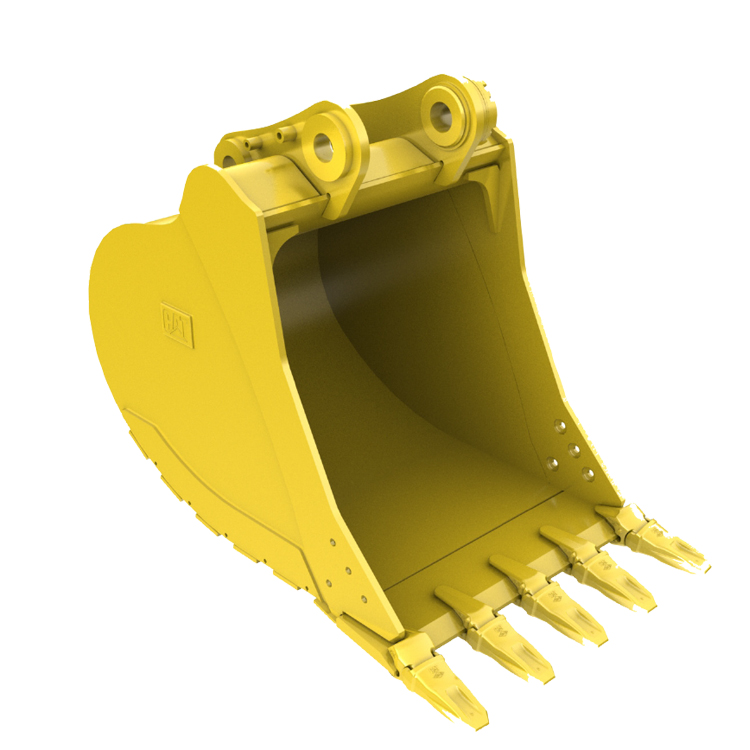

Four Durability Categories for Cat Hydraulic Excavator Buckets

General Duty

For digging in low impact, lower abrasion materials such as dirt, loam, and mixed compositions of dirt and fine gravel.

Example: Digging conditions in which General Duty tip life exceeds 800 hours.

Typically larger General Duty Buckets are the most popular sizes, and are used by site developers to mass excavate in low abrasion applications.

1.Lighter structures decrease load time and increase the weight that can be lifted.

2.Standard size adapters and tips.

3.Sidebars are pre-drilled for optional sidecutters.

4.On 374 and 390, sidebars are pre-drilled for optional sidecutters and sidebar protectors.

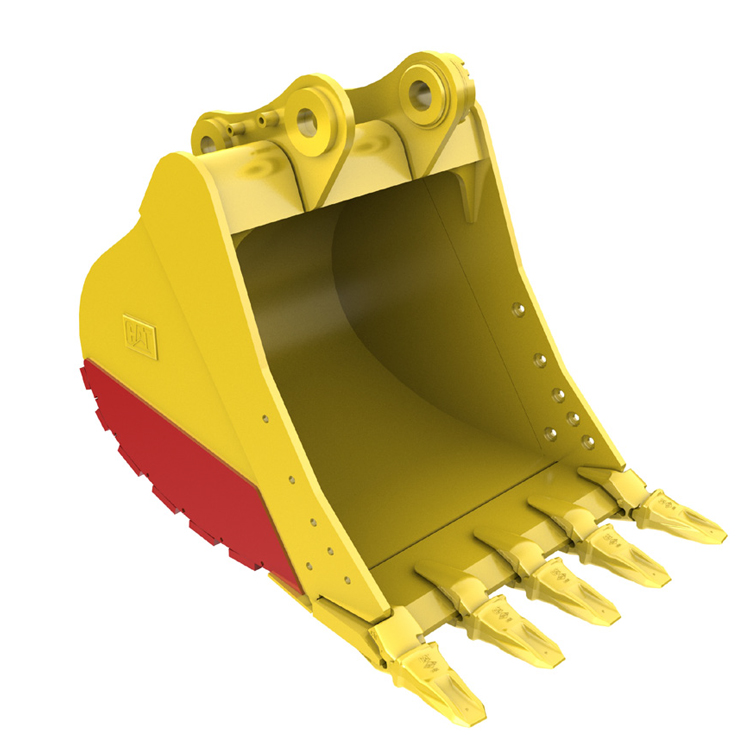

Heavy Duty

The most popular excavator bucket style. A good “center line” choice, or starting point, when application conditions are not well known.

For a wide range of impact and abrasion conditions including mixed dirt, clay and rock. Example: Digging conditions where Penetration Plus tip life ranges from 400 to 800 hours.

Heavy Duty Buckets are recommended for trenching in utilities work, and for the general contractor working in a variety of different situations.

1. Thicker bottom and side wear plates than General Duty Buckets for more durability.

2. Adapters and tips for 319-336 buckets are up sized for enhanced performance and durability.

3. Sidebars are pre-drilled for optional sidecutters, and in many instances, sidebar protectors.

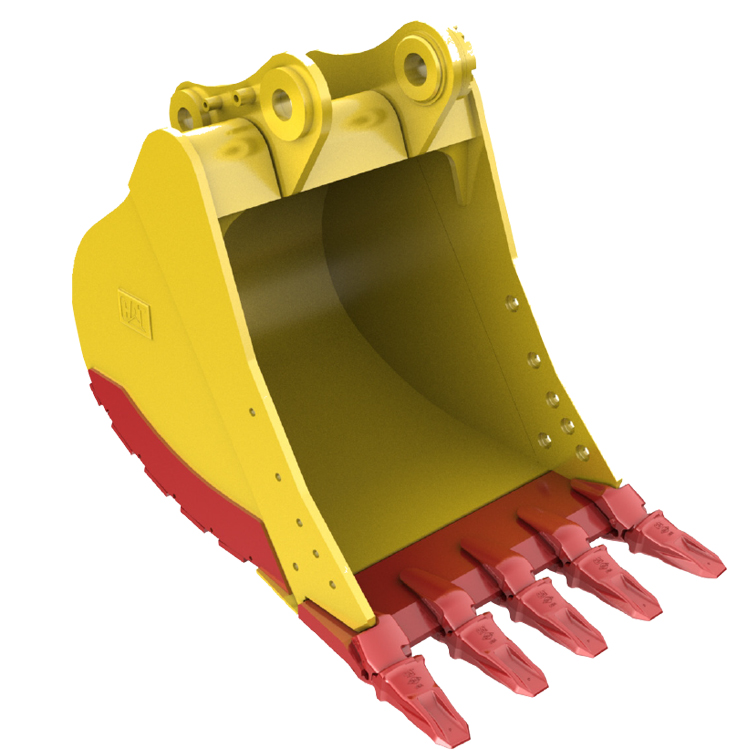

Severe Duty

For higher abrasion conditions such as well shot granite and caliche. Example: Digging conditions where tip life ranges from 200 to 400 hours with Penetration Plus tips.

1. Bottom wear plates are about 50% thicker than Heavy Duty Buckets.

2. Side wear plates are about 40% larger than Heavy Duty Buckets for added protection against abrasive and gouging wear.

3.Adapters and tips are sized to accommodate higher loads and abrasion conditions.

4.Sidebars are pre-drilled for optional sidecutters and sidebar protectors for 320 and larger buckets.