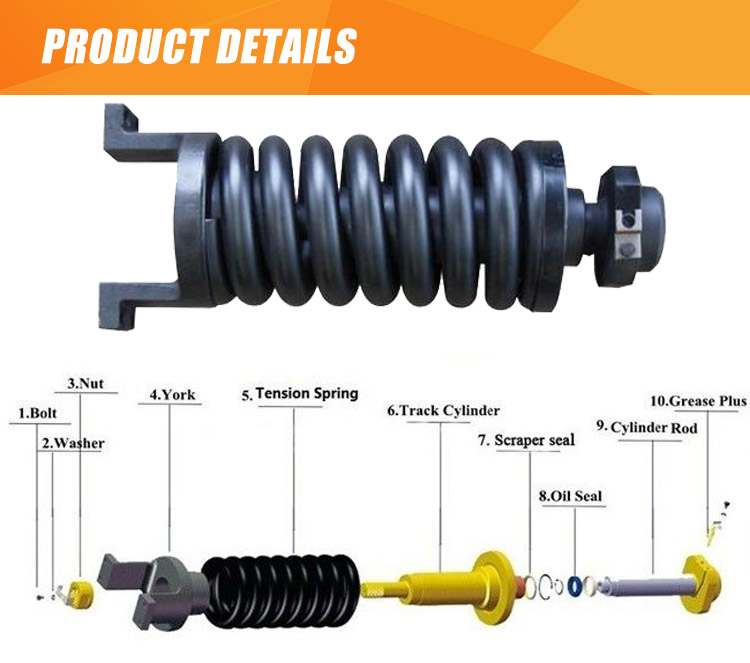

GT Track Adjuster Assembly (Tension Devices) Advantages

Piston rod/Shaft

# key component of track adjuster

# material 40Cr

# Using high precision mirror polishing

# the thickness of chromeplating 0.25mm,(electroplating 0.50mm then gringding to 0.25mm to ensure surfacae hardness HB700) # electroplating- grinding-heat treatment-sand blasting

# High strength spring steel

# Number of recoils is the same as original parts

# Roughness as well as original material

# Produce according to the OEM standards

# Taped end spring: stable, OEM need, stonger stress

# Standard spring option

# fully inspected

| TYPE | APPLICATION | COMPARISION |

| Taped End Spring | OEM need: like original Komatsu, Caterpillar etc | 1.Whole unit is more stable 2.Spring head broken rate can lower70% |

| Standard Spring | After market | Economic price |

Track cylinder

# precision casting

# Rolling surface treatment processing inside

# Gloss surface # Track cyliner surface finish RA<0.2 (inner and Outer)

# Track cylinder and screw pin was press together . (other supplier weld them together)

OEM design:Two grease valve(In & Out) Top quality

| Comparision | |||

| Item | Material | Treatment | U'Price USD |

| exepensive one | 45# steel | normalizing+machining+hardening&tempering, low risk of leaking or pressure drop | 5 |

| cheap one | A3 steel | heat treatment onle on head, high risk of leaking or pressure drop | 1 |

| The whole cylinder pressure inside is more than 600Mpa, if nipple leaked oil, the complete machine undercarriage would be wom out soon | |||

Quality Control System

Raw materials inspection, semi-finished prodcuts in-line inspection and final inspection. Suitable technology manufacturing processes and quality control system to ensure products quality and traceability.

GT AvailableTrack Adjuster Assemblies

| CAT312 | PC220-7 | EX100/120 | FL4 | DH220 |

| CAT E200B | PC300-5 | EX200-1/3/5 | D5/D6 inner cylinder | DH280/300 |

| CAT 320 | PC300-7 | EX300-1/3/5 | D31 | DH350 |

| CAT 320C | PC350/360 | EX400-3/5 | ZAX120 | R55/60-7/65-5/7 |

| CAT 320D | PC400-5 | EC55 | ZAX200-1 | R130-5/7 |

| CAT 330 B/C/D | PC400-7 | EC210-460 | ZAX200-3/5 | R210LC-7 |

| PC60-5 | EX60-1 | SK60 | ZAX330 | R220LC-7 R225 |

| PC100-5/120-5 | EX60-3 | SK100-350 | DH55 | R300/R350 |

| PC200-5/7 | EX60-5 | SH100-300 | DH80 | R465 |