Hydraulic Quick Coupler To Fit Excavators From 1 to 60 tons.

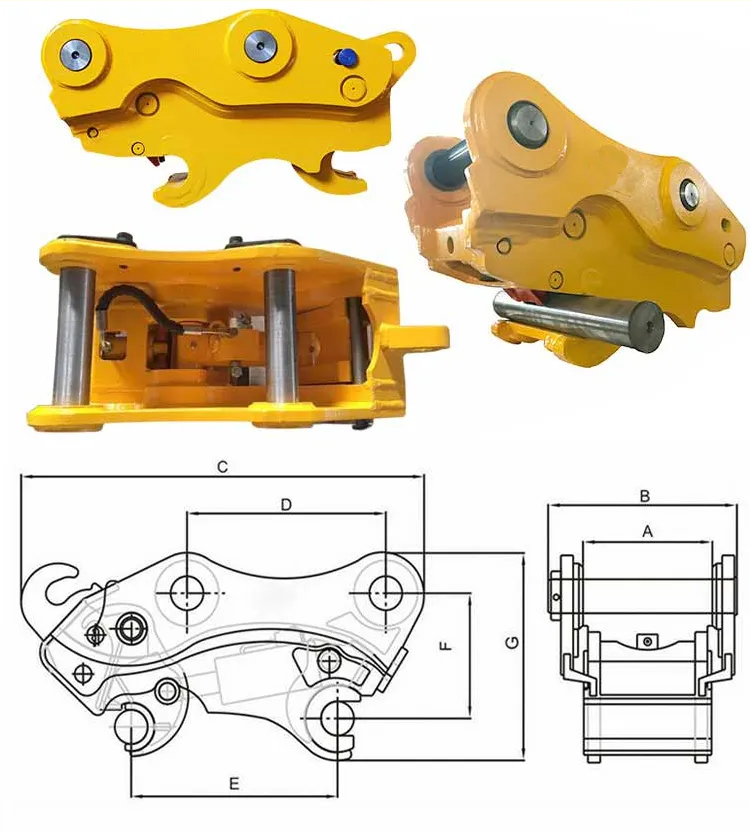

Quick Coupler Show

Quick Coupler Description

Production Description

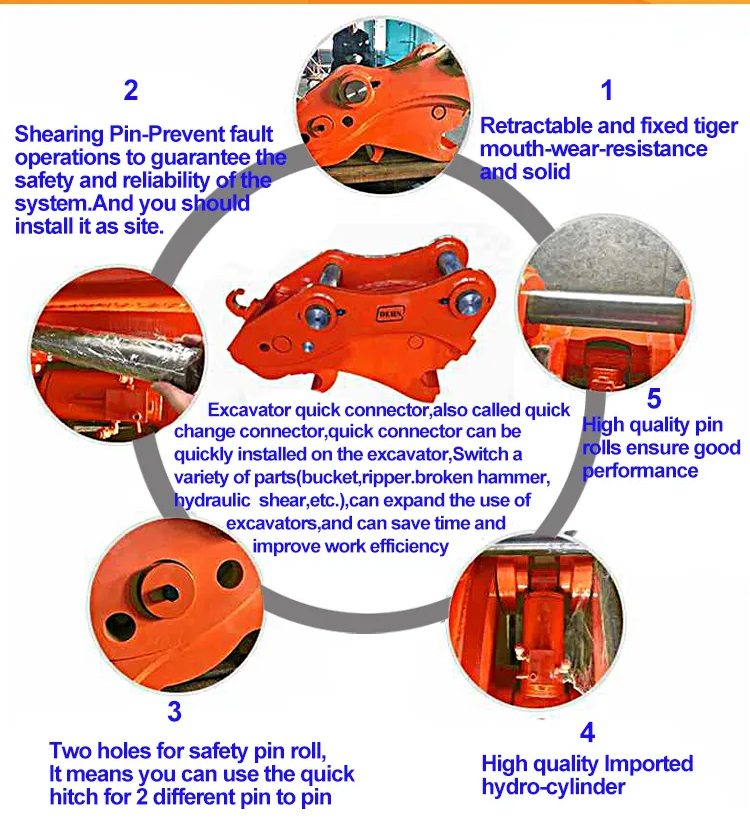

By installing GT Excavator Quick Hitch, also go by Quick Coupler, to your excavator, you can turn it into a MULTI-tasking, MULTI-functional machine. It makes the switching much easier among excavator attachments and increasing the machine productivity and efficiency greatly. Our produdct's high efficiency and durability will save you lots of trouble and boost your projects' return.

Features

1) Use high-strength material ; suitable for various models of 4-45 tons.

2) Use the safety device of the hydraulic control check valve to ensure safety, convenient operation and improve work efficiency.

3) The excavator configuration parts can be replaced without modification or disassembly of the pin shaft, so the installation is quick and the work efficiency can be greatly improved.

4) Only takes ten seconds to attach the quick hitch to your machine.

Material

Steels are being called differently among different countries. Here is the data that might gave you a better understanding of the steel we used for manufacturing Excavator Quick Hitch.

| Material | Code | Related Chemical Composition | Hardness(HB) | Extension(%) | Drag and extension intensity (N/mm2) | Bend Intensity (N/mm2) | ||||

| C | Si | Mn | P | S | ||||||

| Alloy | Q355B | 0.18 | 0.55 | 1.4 | 0.03 | 0.03 | 163-187 | 21 | 470-660 | 355 |

| Chinese High-Strength alloy | NM360 | 0.2 | 0.3 | 1.3 | 0.02 | 0.006 | 360 | 16 | 1200 | 1020 |

| High-Strength alloy | HARDOX-500 | 0.2 | 0.7 | 1.7 | 0.025 | 0.01 | 470-500 | 8 | 1550 | 1 |

Excavator Quick Hitch can be used on the excavators or loader to change every accessory,such as bucket,breaker,shear.etc,easily and quickly,which has widened the use range of the excavators and saved a lot of time.

Quick Coupler Testing

Quick Coupler Model We Can Supply

| Information For Reference | |||||||||||

| Category | Unit | MINI | GT-02 | GT-04 | GT-06 | GT-08 | GT08-S | GT-10 | GT-14 | GT-17 | GT-20 |

| Total lenght | mm | 300-450 | 520-542 | 581-610 | 760 | 920-955 | 950-1000 | 965-1100 | 980-1120 | 1005-1150 | 1100-1200 |

| Total Width | mm | 150-250 | 260-266 | 265-283 | 351-454 | 450-483 | 445-493 | 534-572 | 550-600 | 602-666 | 610-760 |

| Total Height | mm | 225-270 | 312 | 318 | 400 | 512 | 512-540 | 585 | 550-600 | 560-615 | 620-750 |

| Arm open width | mm | 82-180 | 155-172 | 181-205 | 230-317 | 290-345 | 300-350 | 345-425 | 380-450 | 380-480 | 500-650 |

| Pins center distance | mm | 95-220 | 220-275 | 290-350 | 350-400 | 430-480 | 450-505 | 485-530 | 550-600 | 520-630 | 600-800 |

| Pin Diameter(Ø) | mm | 20-45 | 40-45 | 45-55 | 50-70 | 70-90 | 90 | 90-100 | 100-110 | 100-110 | 120-140 |

| Cylinder strok | mm | 95-200 | 200-300 | 300-350 | 340-440 | 420-510 | 450-530 | 460-560 | 510-580 | 500-650 | 600-700 |

| Vertical pins center distance | mm | 170-190 | 200-210 | 205-220 | 240-255 | 300 | 320 | 350-370 | 370-380 | ||

| Weight | kg | 30-40 | 50-75 | 80-110 | 170-210 | 350-390 | 370-410 | 410-520 | 550-750 | 550-750 | 1300-1500 |

| Working pressure | kgf/cm3 | 30-400 | 30-400 | 30-400 | 30-400 | 30-400 | 30-400 | 30-400 | 30-400 | 30-400 | 30-400 |

| Necessary flow | l | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 |

| Suitable excavator | ton | 0.8-4 | 4-6 | 6-9 | 10-16 | 18-25 | 25-26 | 26-30 | 30-40 | 40-52 | 55-90 |

| Strong safety pin at accurate | High-abrasive front tiger mouth design | Reinforced cylinder with imported oil seals(Simrit Germa-ny brand)position | |||||||||