Hydraulic Rotating Grab Used in Sugar Cane Wood Pipe Grass

Hydraulic Rotating Grab

Feature

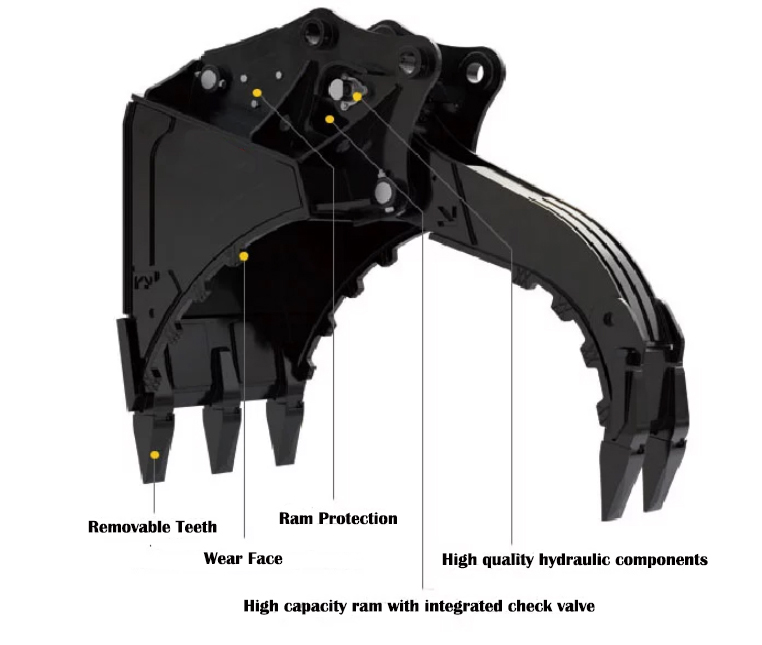

•Imported motor, stable speed, large torque, long service life.

•Use special steel, light, high elasticity, high were-resistance

•Maximum open width, Minimum weight an Maximum performance.

•can be clockwise,counterclockwise 360 degrees free rotation.

•Use special rotating gear that can be pro-long products life an reduce the maintenance cost.

Here's how a hydraulic rotating grab typically works:

1. Hydraulic System: The grab is powered by a hydraulic system, which uses hydraulic fluid to generate power and control the movements of the grab. The system consists of a hydraulic pump, valves, and hoses.

2. Opening and Closing: The grab's jaws or tines can be opened and closed using hydraulic cylinders. When the hydraulic fluid is directed to extend the cylinder, the jaws open. Conversely, when the fluid is directed to retract the cylinder, the jaws close, gripping the object.

3. Rotation: The hydraulic rotating grab also has a hydraulic motor that allows it to rotate. The motor is connected to the grab's frame and can be controlled by the operator. By directing hydraulic fluid to the motor, the operator can make the grab rotate clockwise or counterclockwise.

4. Control: The operator controls the opening, closing, and rotation of the grab using hydraulic control valves. These valves are typically operated by joysticks or buttons in the operator's cabin.

5. Application: Hydraulic rotating grabs are commonly used in various industries such as construction, demolition, waste management, and forestry. They are used to handle materials like rocks, logs, scrap metal, waste, and other bulky items.

It's important to note that specific designs and functionalities may vary between different models and manufacturers of hydraulic rotating grabs.

Model we can supply

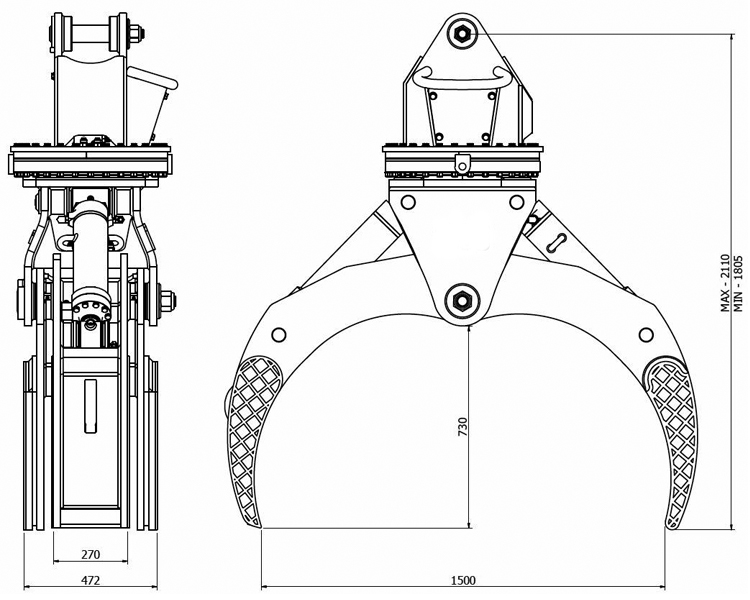

| Item / Model | Unit | GT100 | GT120 | GT200 | GT220 | GT300 | GT350 |

| Suitable Excavator | ton | 4-6 | 7-11 | 12-16 | 17-23 | 24-30 | 31-40 |

| Weight | kg | 360 | 440 | 900 | 1850 | 2130 | 2600 |

| Max Jaw Opening | mm | 1200 | 1400 | 1600 | 2100 | 2500 | 2800 |

| Working Pressure | bar | 110-140 | 120-160 | 150-170 | 160-180 | 160-180 | 180-200 |

| Set Up Pressure | bar | 170 | 180 | 190 | 200 | 210 | 200 |

| Working Flow | L/min | 30-55 | 50-100 | 90-110 | 100-140 | 130-170 | 200-250 |

| Cylinder Volume | ton | 4.0*2 | 4.5*2 | 8.0*2 | 9.7*2 | 12*2 | 12*2 |

Grap Application

A hydraulic rotating grab is a versatile tool commonly used in various industries. Some of the applications of a hydraulic rotating grab include:

1. Construction: Hydraulic rotating grabs are frequently used in construction sites for tasks such as loading and unloading materials, sorting debris, and handling heavy objects like rocks and concrete blocks.

2. Demolition: In demolition projects, hydraulic rotating grabs are essential for safely and efficiently removing debris, dismantling structures, and clearing the site.

3. Waste management: Hydraulic rotating grabs are often utilized in waste management facilities to handle and sort different types of waste, such as recyclables, organic materials, and general waste.

4. Forestry: In the forestry industry, hydraulic rotating grabs are employed for handling logs, branches, and other vegetation. They can be attached to excavators or cranes to facilitate efficient logging operations.

5. Scrap metal industry: Hydraulic rotating grabs are commonly used in scrapyards for sorting and transporting various types of metal scrap. They enable operators to handle large volumes of scrap metal quickly and efficiently.

6. Port and harbor operations: Hydraulic rotating grabs are utilized in port and harbor operations for loading and unloading cargo from ships or containers. They are particularly useful for handling bulk materials like coal, sand, and gravel.

7. Mining: In mining operations, hydraulic rotating grabs are used for various tasks, including loading and unloading materials, sorting ore, and handling rocks and debris.

These are just a few examples of the applications of hydraulic rotating grabs. Their versatility and ability to handle heavy loads make them valuable tools in many industries