Undercarriage Parts with Model PC8000 EX5500 EX8000

PC2000 Spare Parts Description

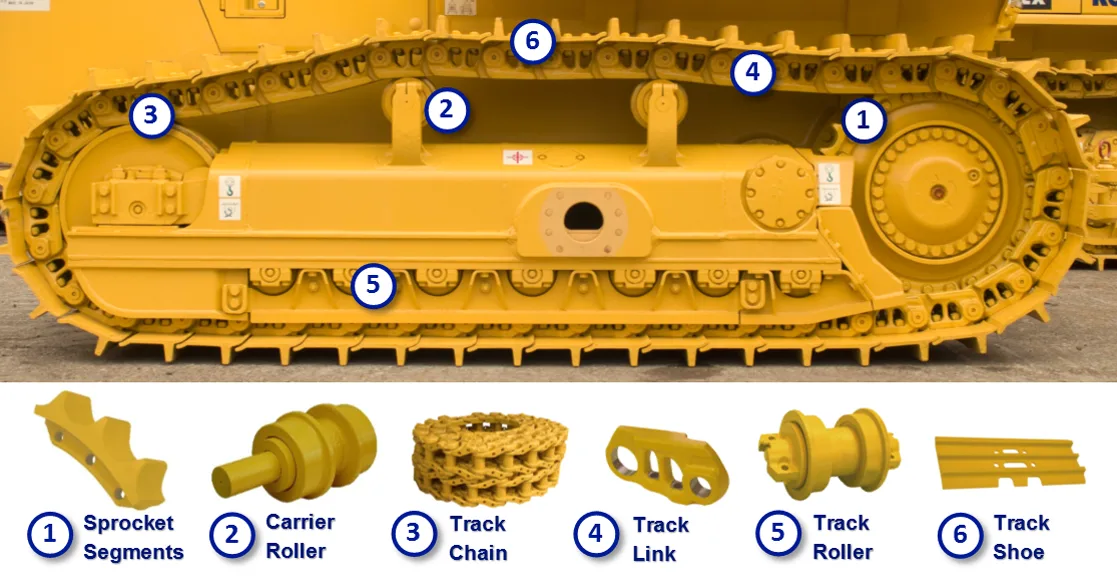

- Track Shoes: These components make direct contact with the ground, providing mobility for the machine. They are usually made of high-strength steel to withstand heavy loads and harsh working conditions.

- Track Chains: These connect the track shoes and transmit power, ensuring smooth operation of the machine. The design of track chains must ensure wear resistance and reliability.

- Track Rollers: These support the weight of the machine and help the tracks move over uneven terrain. Regular maintenance is required to ensure smooth operation.

- Idlers: These maintain the tension of the tracks and prevent them from derailing. They are typically located at the front of the tracks.

- Sprockets: These engage with the track chains and are responsible for transferring engine power to the track system. The design of sprockets must ensure durability and efficient power transmission.

PC2000 Spare Parts Production Line

Large Machine We can Supply

| Model | OEM | Products | Qty | Weight( k g ) | Material |

| EX2500 | 4352140 | Track roller | 16 | 493.00 | 4340 |

| 9173150 | Carrier roller | 6 | 123.00 | 4340 | |

| 1029150 | sprocke | 2 | 1398.00 | 32CrNiMo | |

| 9134236 | idler | 2 | 1287.00 | 32CrNiMo | |

| EX3500 | 4317447 | Track roller | 16 | 676.76 | 4340 |

| 9066271 | Carrier roller | 6 | 214.28 | 4340 | |

| 1029151 | sprocket | 2 | 2180.42 | 32CrNiMo | |

| 9185119 | idler | 2 | 1738.17 | 32CrNiMo | |

| EX5500 | 4627351 | Track roller | 14 | 1363.90 | 4340 |

| 9161433 | Carrier roller | 6 | 271.25 | 4340 | |

| 1029152 | sprocket | 2 | 3507.18 | 32CrNiMo | |

| 1025104 | idler | 2 | 3201.91 | 32CrNiMo | |

| EX8000 | 9279019 | Track roller | 14 | 1599.82 | 4340 |

| 9279020 | Carrier roller | 2 | 386.00 | 4340 | |

| sprocket | 2 | 6429.00 | 32CrNiMo | ||

| idler | 2 | 5447.00 | 32CrNiMo | ||

| PC5500 | 94428840/95641340 | Carrier roller | 4 | 247.00 | 4340 |

| 91352440 | Track roller | 14 | 675.00 | 4340 | |

| PC4000 | 89590440 | LOWER ROLLER | 14 | 507.00 | 4340 |

| 42968740(97077240) | UPPER ROLLER | 6 | 246.00 | 4340 | |

| 88711040 | DRIVE TUMBLER | 2 | 3,475.00 | 32CrNiMo | |

| 42969740 | IDLER | 2 | 2,648.00 | 32CrNiMo | |

| 93049640 | T R A C K S | 98 | 479.00 | 32CrNiMo | |

| PC8000 | 938-789-40 | Idler Assembly | 2 | 6,130.00 | 32CrNiMo |

| 938-790-40 | Lower Roller Assy | 16 | 790.00 | 4340 | |

| 938-795-40 | Upper RollerAssy | 6 | 302.00 | 4340 | |

| 938-788-40 | Drive Tumbler Assy | 2 | 5,994.00 | 32CrNiMo | |

| 936-695-40 | Track Shoe | 96 | 1,160.00 | 32CrNiMo |

Maintenance Tips

Maintaining the undercarriage parts of PC5500 and PC4000 excavators is crucial for ensuring their long-term reliability and performance. Here are some maintenance tips:

- Regular Inspection and Cleaning:

- Regularly remove dirt, debris, and other obstructions from the tracks and undercarriage to prevent wear and damage.

- Inspect all components for signs of cracks, wear, or other damage.

- Lubrication:

- Regularly lubricate the track rollers, idlers, and sprockets to reduce friction and wear.

- Ensure the use of appropriate lubricants and follow the manufacturer's recommendations.

- Tension Adjustment:

- Regularly check and adjust the track tension. Tracks that are too loose can increase wear risk, while overly tight tracks can put extra stress on components.

- Check the tension of idlers and track chains to ensure they are within the recommended range.

- Replacement of Worn Parts:

- Replace worn track shoes, track chains, and other critical components based on usage and wear levels.

- Use manufacturer-recommended original parts to ensure optimal performance and compatibility.

- Regular Maintenance Schedule:

- Develop a detailed maintenance schedule, including inspection, lubrication, and replacement timelines for all undercarriage components.

- Keep records of each maintenance activity to track the lifespan and performance changes of the components.

| Description | OEM Spare parts number |

| Track roller | 17A-30-00070 |

| Track roller | 17A-30-00180 |

| Track roller | 17A-30-00181 |

| Track roller | 17A-30-00620 |

| Track roller | 17A-30-00621 |

| Track roller | 17A-30-00622 |

| Track roller | 17A-30-15120 |

| Track roller | 17A-30-00070 |

| Track roller | 17A-30-00170 |

| Track roller | 17A-30-00171 |

| Track roller | 17A-30-00610 |

| Track roller | 17A-30-00611 |

| Track roller | 17A-30-00612 |

| Track roller | 17A-30-15110 |

| Track roller | 175-27-22322 |

| Track roller | 175-27-22324 |

| Track roller | 175-27-22325 |

| Track roller | 17A-27-11630 (GруPPа SegmentоV) |

| Track roller | 175-30-00495 |

| Track roller | 175-30-00498 |

| Track roller | 175-30-00490 |

| Track roller | 175-30-00497 |

| Track roller | 175-30-00770 |

| Track roller | 175-30-00499 |

| Track roller | 175-30-00771 |

| Track roller | 175-30-00487 |

| Track roller | 175-30-00485 |

| Track roller | 175-30-00489 |

| Track roller | 175-30-00488 |

| Track roller | 175-30-00760 |

| Track roller | 175-30-00480 |

| Track roller | 175-30-00761 |