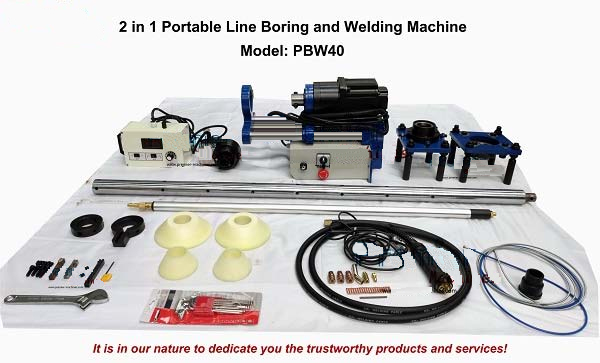

PBW40 2 in 1 Portable Line Boring & Welding Machine for sale

Introduction:

Our 2 in 1 Portable line boring and welding machine is mainly used for processing different kinds of concentric interval bore and side-by-side porous with continuous cutting or do the bushing after re-boring, it is in high efficiency and accuracy.

For the welding part, it can be widely used to weld and repair the hole of large-sized machinery, pivot pin hole of earth moving equipment and bearing hole. It is ideal and necessary equipment for the industry and mining enterprise and on -site engineering repairing

Application

1. Processing and repairing the rotation hole, reaming, pin-hole, installation and remain hole

of structure member for kinds of machine.

2. The spindle adopts 220V motor with the feature of higher torque at lower speed.

3. There is no vibration for the axial movement and cutting process to ensure stable cutting.

4. Processing and repairing concentric interval hole of excavator and crane.

5. Processing porous one-time, ensuring porous in alignment.

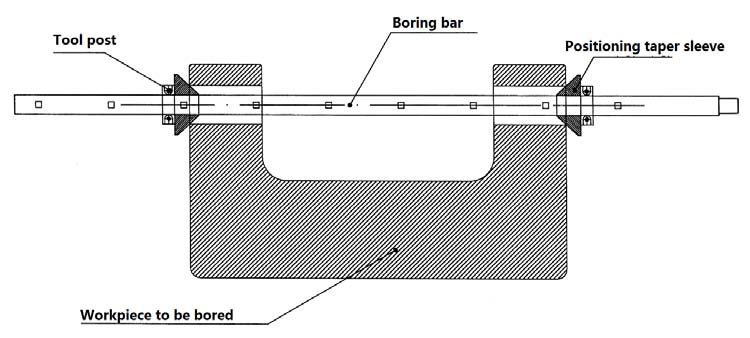

Machining Diagram for Boring

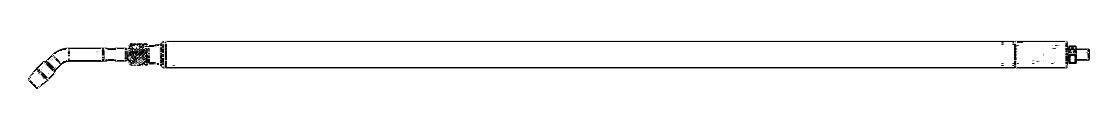

Machining Diagram for Welding

Main controller

Welding Torch

| Model | PBW40 |

| Min. boring dia. | 45mm |

| Max. boring dia. | 200mm |

| Boring bar | 40 x 1500mm |

| Spindle speed | 0 to 80rpm/min |

| Max. stroke | 300mm (Standard) Max. stroke can be extended as request. |

| Max. cutting depth | 2mm (single side) |

| Motor power | 1.5Kw, DC motor |

| Roughness of boring | Ra3.2 |

| Roundness tolerance | ≤0.02mm |

| Net. weight | 100kg |

| Specification for Welding: | |

| Working voltage | AC 220V 50Hz |

| Max. power | 100w |

| Spindle rotation speed | Stepless 0 to 20r/min |

| Range of welding I.D. | Φ45 to 200mm |

| Axial travel | 255mm |

| Dia. of welding stick | 1.0mm |

| G.W. | 11kg |

| Dimension | 400*210*290mm |

| Ambient temperature | -10℃~+40℃ |

| Storage temperature | -25℃~+55℃ |

| Relative humidity | 20℃≤85% 40℃≤50 |