Breakdown for Rubber tracks

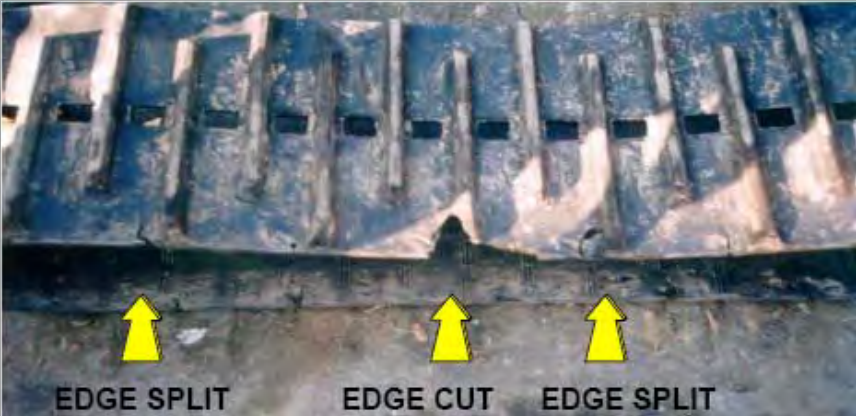

1.Cuts or cracks in the rubber track

CAUSE

1) Sharp objects or driving on uneven surfaces Riding on rough surfaces with obstacles such as rocks or other objects you may encounter excessive stress on the edge of the track that could cut, crack or tear.

2) Interference with the structure or machine components

If the machine continues to work with rubber tracks out driving, they can be caught in the machine structure or undercarriage damaged. Even when the voltage is not adequate, the track could slip out of gear. Could therefore occur breakage caused by the sprocket and the roller track on the loose.

During the tour route in these conditions, the track could be broken and deformed due to the rugged terrain or foreign matter trapped between the track and the same structure, which could cause cuts, tears or lacerations.

-PREVENTION

-Avoid use on uneven surfaces, steep or too narrow

-If possible, avoid long journeys that cause a lot of friction on the track

-Always check the tension. If the track is out driving, the car must be stopped immediately for inspection.

-After each cycle, remove the debris from the structure (or rollers) and the track.

-The operator must avoid contact between the machine and concrete walls, ditches and sharp edges.

CAUSE

1) The following circumstances, you may accumulate too much pressure on the tension of the track, causing the rupture of the steel bead.

- An incorrect voltage may result in the separation of track from the sprocket or idler wheel. In this If the idler wheel or sprocket metal could end up on the projection of the soul.

- Incorrect installation of roller, sprocket and / or idler wheel.- The track is blocked or trapped by rocks or other objects.

- Curve rapid and careless driving.

2) Corrosion caused by moisture

-The moisture penetrates the track through the cuts and splits, and may cause corrosion of the steel curb and the breakage.

-PREVENTION

-It's important to regularly verify that the level of tension is the recommended- Avoid working on surfaces with many stones or other foreign matter, and if unavoidable, minimize the impact on the track driving slowly and carefully- Do not place shortcuts on rocky or uneven surfaces, and if unavoidable groped or otherwise turning to widen the turn carefully.

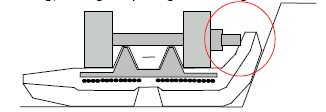

2.Detachment metal soul

When an excessive impact on the soul rests in a metal embedded in the track, it could detach the base of the track itself.

-CAUSE

1) The metal core of the track could be separated or damaged by excessive external forces. These forces may occur in the following cases:

-- Not following the manufacturer's specifications (voltage regulation of the wrong use of undercarriage components are worn out, ...) could get out of the track guide. In this case, the idler wheel or sprocket metal could end up on the projection of the soul, detached from the track.

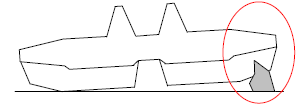

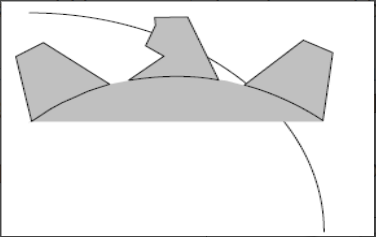

- If the gear is damaged (see picture below), the pressure will burden the soul of metal that could break and detach from the track.

2) Corrosion and chemical penetration

- The metal core adheres perfectly inside the track, but the adhesion force can be reduced by corrosion or ingress of salt or other chemicals after use.

-PREVENTION

- Periodically check the tension kept within the recommended levels.

- The user must operate in accordance with the instructions provided in manual or technical specifications provided by the manufacturer of the machine.

- Do not place shortcuts on rocky or uneven surfaces, and if unavoidable, turn slowly and carefully.

- Wash thoroughly with water and dry the car after each use.

- It's a periodic monitoring of wheels and rollers.

3.Cut at an angle on

-CAUSE

When the rubber track passes over sharp rocks or other rough terrain, it may lead to cuts on the shoe. Through these cuts, the curb steel could be reached by water or other chemicals thatcould cause corrosion and a rupture of the curb itself.

-PREVENTION

When operating on land such as forests, dirt roads, concrete, construction, covered with sharp stones and rocks, the operatormust:

- Drive slowly paying attention.

- bend and change direction with wide-ranging.

- Avoid high speeds, tight turns and overloads.

- Carry the other tracked vehicles in case of long journeys.