SH120 Front Idler SUMITOMO Idler Crawler Machinery Excavator Spare Parts Undercarriage Parts

Product Information

| Material | 40SiMnTi |

| Finish | Smooth |

| Colors | Black or yellow |

| Technique | Forging casting D85ESS-2 Idler |

| Surface Hardness | HRC48-54,deepth:4mm-10mm |

| Warranty time | 2000 hour |

| Certification | ISO9001-9002 |

| FOB Price | FOB Xiamen USD 50-450/Piece |

| MOQ | 2 piece D85ESS-2 Idler |

| Delivery Time | Within 30 days after contract established |

Idler Characteristic

A Genuine Front Idler

Reduces Bearing Stress 50% To Decrease Bearing Loads And Increase Component Lif

Heavy Duty Rock Guards Protect Against Damage From Dirt And Debris

Helps To Lower Mine Operating Costs By Extending Crawler System Life, Minimizing Unplanned Downtime

Provides Greater Track Efficiency By Increasing Bearing Area And Lube Distribution

Increased Productivity

Splined Connection Between Idler And Shaft Increases Reliability And Matches Idler Life With That Of Other Lower Works Components

Bearing Blocks With Bushings Can Be Removed Without Breaking The Track

Dedicated Lube Injectors Supply Lubricant To Critical Wear Surfaces

Lower Total Cost Of Ownership

50% Less Bearing Stress Reduces Bearing Loads And Increases Component Life

Rotating Shaft Within Stationary Bushings Produces Less Contact Stress And Wear

Heavy-Duty Rock Guard Prevents Dirt And Debris From Damaging Parts

Enhanced Safety

Longer Crawler System Life Increases Change-Out Intervals Reducing Employee Exposure To Safety Risks From System Change-Outs And Component Replacement

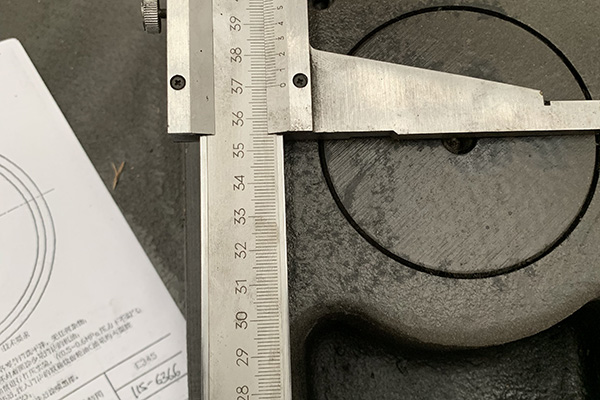

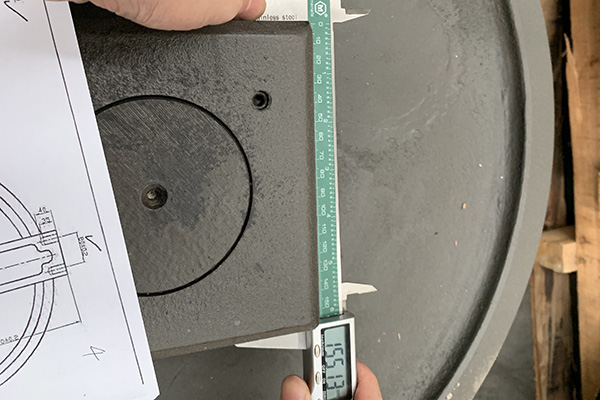

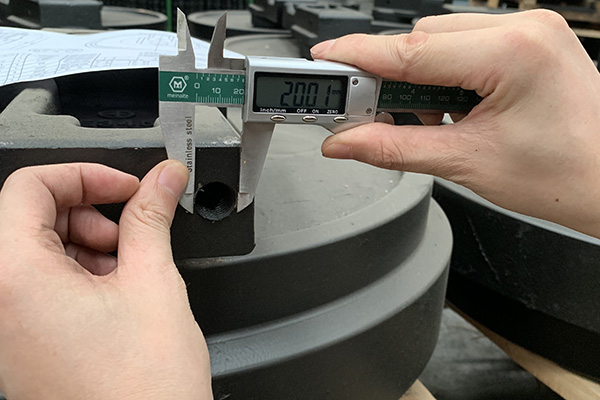

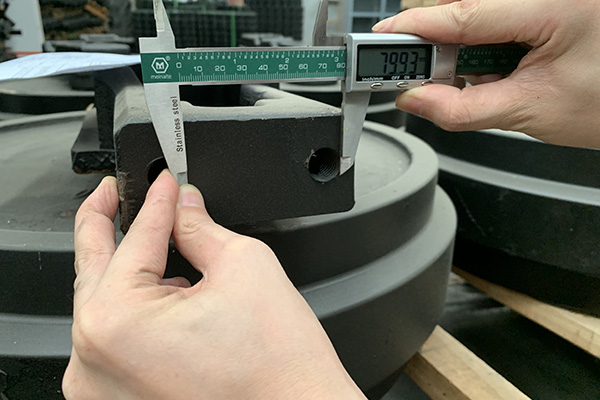

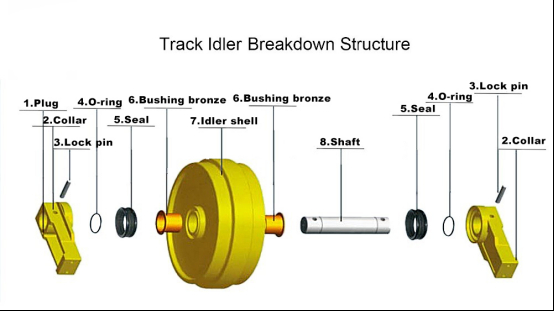

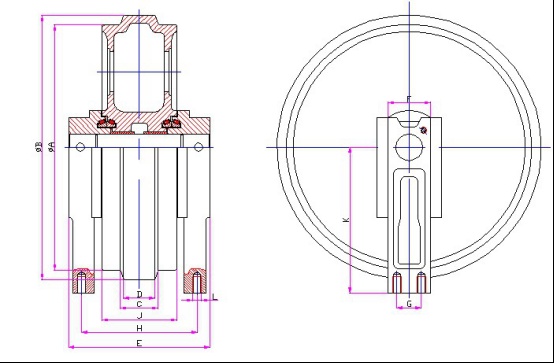

Design/Structure/Main Dimensions Of Installation

Partial list

|

MAIN PARAMETERS |

||||||||

|

Brand |

Model |

Main Dimensions Of Installation |

||||||

|

A |

B |

D |

L |

M |

N |

O |

||

|

SUMITOMO |

SH120 |

540 |

500 |

140 |

20 |

265 |

80 |

60 |

|

SH200 |

540 |

500 |

160 |

40 |

285 |

90 |

65 |

|

|

SH280 |

540 |

500 |

160 |

40 |

285 |

90 |

65 |

|

Other parts we can supply

|

models |

A |

B |

C |

D |

E |

F |

G |

H |

K |

L |

J |

|

D20 |

417 |

442 |

48 |

44 |

250 |

70 |

42 |

206.5 |

178 |

4-M12 |

100 |

|

D31 |

520 |

548 |

52 |

44.4 |

333 |

74 |

50 |

220 |

225 |

4-M16 |

118 |

|

D50 |

680 |

720 |

85 |

79 |

335 |

217/287 |

402.5 |

6-M16 |

164 |

||

|

D60 |

680 |

720 |

104 |

97 |

388 |

242/313 |

450 |

6-M16 |

190 |

||

|

D85 |

730 |

772 |

105 |

228 |

65/95 |

250/354 |

590 |

8-M20*2.5 |

205 |

||

|

D155 |

800 |

848 |

122 |

112 |

610 |

290/400 |

8-M20 |

245 |